The Display Innovations Panel Lock

The panel lock latch assembly "The Panel Lock" by Display Innovations is unique from the other styles of panel locks, roto locks and fasteners available for a variety of reasons. One of the first details that make them unique is we are the only company that makes them. These latch assemblies are contract manufactured domesticly specificly for Display Innovations.

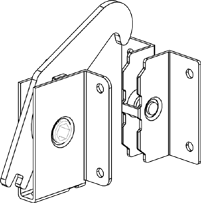

Another of the features that make our panel locks unique are the hooks and cams. Some of the other varieties of locks available use a bent rod for a hook and can be subject to bending. Other styles use lighter gage steel formed into a cam shape and then assembled. Both of these styles have been known to fail. Our panel lock hook is stamped from a solid piece of .135 thick (10 gage) steel so nearly impossible to bend or break under normal usage.

The cam is constructed of stamped, formed steel assembled to allow the cam to rotate time after time, year after year without failure.

The panel lock body consists of .066 (15 gage) steel formed into its final shape. It is formed out of one solid piece of steel so there are no other connections able to fail during use.

The hook and cam assembly are then installed into the main body along with the hex barrel. The hex barrel is the center shaft where the hex wrench is inserted to turn the hook and cam.

When the cam is rotated all the way to the left (counter clockwise) the hook and cam lock into the "parked" position as shown. This is the normal position for the hooks so they do not move out of position during handling, assembly or shipping.

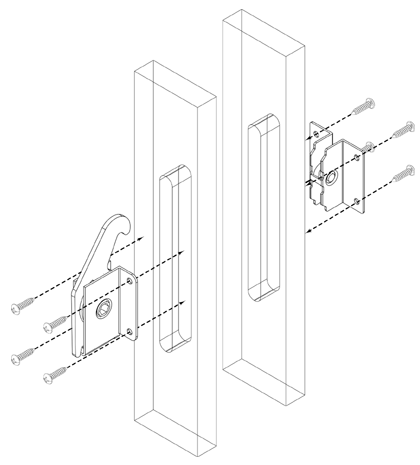

Panel Lock Installation

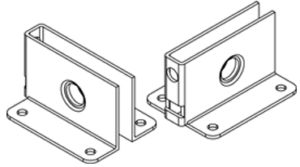

Another of the unique features of our panel lock is the installation. The other styles of panel locks on the market typically mount from the outside. This installation typically requires two different routing steps, one to route the opening through the parts to be joined and the second to create a recess area for the lock mounting plates. Our lock only requires an opening 1/2" wide approximately 6" long.

Another unique feature of our lock that sets it apart from the other styles is how it is mounted. With the other styles of locks the lock assembly is installed from the outside. This method of mounting relies on the strength of the fastener for all its strength. With this style of mount if the screw holding the lock in place strips or fails, the lock connection fails.

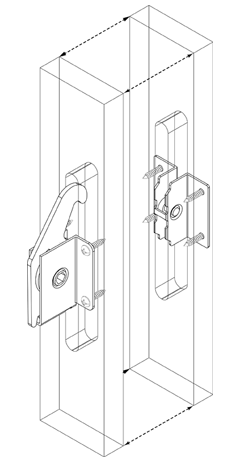

Our locks are installed on the rear face of the material to be joined. By mounting the hook and strike behind the material to be pulled together the connection does not rely on the strength of the fastener. Typically, four #8 x 3/4" pan head screws are used to hold the lock hook and lock strike in place.

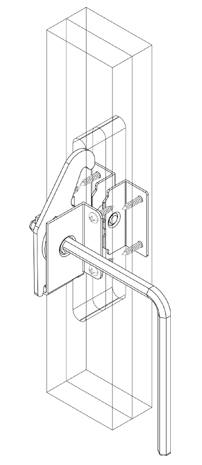

Once the hook and strike are installed, the two surfaces to be joined are brought together in alignment prior to locking. It is highly recommended that some type of alignment aid be used during assembly; this can be slot and splines, pucks, alignment pins, dowel of other desired method. The alignment aids help guarantee the two objects to be joined stay aligned before and during locking.

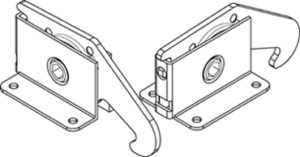

A panel lock wrench (hex wrench) is used to rotate the latch assembly for locking and unlocking. By rotating the cam wrench clockwise when mounted as shown, the hook rotates outward and downward until it engages the strike pin installed in the other component to be joined.

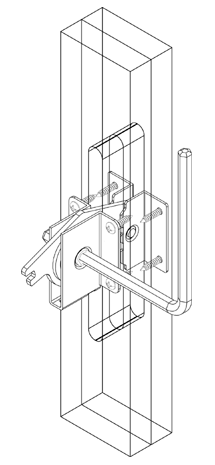

By continuing to rotate the wrench the cam now begins to turn. As the cam turns it begins to draw the hook backwards towards the main body. The exact amount of pressure this latch produces pulling the components together has not been officially measured but there is a VERY substantial amount of power generated by these latches.

Once the cam completes its rotation and the hook is fully drawn back the cam clicks into its locked position. The latch will now stay locked until the wrench is used to unlock the latch. This ensures a safe and secure connection.

To unlock the latch, rotate the wrench and cam counter clockwise until there is a click in the open position. This now locks the hook and cam in the "parked" or "open" position so it will stay in place until ready to be locked again.

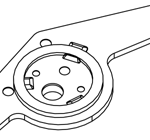

These panel lock latches work especially well in double-sided or sealed installations. We offer an alignment drilling jig that works great to help guarantee the alignment of the wrench access hole and the lock hole. Once the lock is installed and one side is skinned the jig provides a very quick alignment through the panel skin before the panel is sealed with the second side.

Another great feature of these panel locks is the lack of any loose parts or hardware. There are no bolts, or nuts to deal with or loose. As most installation managers know, when it comes time for the show dismantle and bodies are moving quickly, the majority of the bolts and nuts used in many typical connections end up in the pouch or pockets of the dismantle workers. The next time the project needs to be set, the hardware needs to be checked and restocked. With these panel lock latches, the only tool or part needed is the panel lock wrench.

When it comes to trade show exhibit set-ups, theatrical set-ups or other event where components need to be assemble and dismantled repeatedly, time is money and durability is critical. To lock or unlock our panel lock latches, once the parts are aligned it takes approximately three to fives seconds to lock or unlock. Multiply this through out an exhibit set and this time can add up to a substantial savings in time.

As to durability, we know of many cases where the exhibit properties were retired to the dumpster. The panel locks latches were salvaged where practical and reused in the next exhibit. They last.

While these panel lock latches are more expensive than some of the other styles available we firmly believe they make up for the extra cost and have a positive ROE. How much does the extra labor during set-up and dismantle add up to? What about time and material to repair defective or failed latches for the other styles? What is a builder's reputation worth when a latch fails during a set-up or a person is injured as a result? Reputable builders are in business for the long haul and want a product that is also in it for the long haul.

We have sold literally hundreds of thousands of these panel lock assemblies since 1983 and they are still going strong. We strongly feel they are the strongest, most durable latch assembly on the market.

If you have not had the opportunity to experience the panel lock latch assemblies but are seriously interested, contact us and request a sample and we will provide a full working, mounted assembly for testing.